Sebbens Family

We are grateful for an interview with Kevin Sebbens, who lived in the area from when he was born in 1929, apart from some time spent boarding elsewhere when he was a school student.

Some of what he told us is below, together with a couple of tit-bits from other sources.

From Mossy Point Progress Association Record c1980:

- “Sebbens family settled in the area in during 1800s, Jim and Kevin are descendents.

- Sebbens family owned a mine at Bimbimbie [See the page for Mogo Goldfield].

- Jim Sebbens' father worked at Cooks Timber Mill.

- One of the Sebbens family was buried at 'Gravehead' [a small number of graves on Melville Pt,] where the gravestones were destroyed by the developers of Tomakin in the 1960s." [It seems that it was more important to the developers of Sunpatch as a lookout than as an historic cemetery.] For some information on Sunpatch, see the page for Tomago/Tomakin/Sunpatch.

- "Jim Sebbens was born on the sandspit roughly opposite the site of the old timber mill” [that is, opposite the Mossy Pt Boat Ramp].

Some of what he told us is below, together with a couple of tit-bits from other sources.

From Mossy Point Progress Association Record c1980:

- “Sebbens family settled in the area in during 1800s, Jim and Kevin are descendents.

- Sebbens family owned a mine at Bimbimbie [See the page for Mogo Goldfield].

- Jim Sebbens' father worked at Cooks Timber Mill.

- One of the Sebbens family was buried at 'Gravehead' [a small number of graves on Melville Pt,] where the gravestones were destroyed by the developers of Tomakin in the 1960s." [It seems that it was more important to the developers of Sunpatch as a lookout than as an historic cemetery.] For some information on Sunpatch, see the page for Tomago/Tomakin/Sunpatch.

- "Jim Sebbens was born on the sandspit roughly opposite the site of the old timber mill” [that is, opposite the Mossy Pt Boat Ramp].

|

Charcoal. For the last year or so of WW2 Kevin and his father Jim worked full time collecting dry wood from forests near to the Connells Point turnoff from the highway (now the Old Mossy Point Road intersection), there was a set-up there where charcoal was produced. The dry wood was put into steel tanks there and burned slowly to make the charcoal, which was in demand for gas production to run cars and trucks on during petrol rationing, they were fitted with a charcoal burning gas producer on the back. |

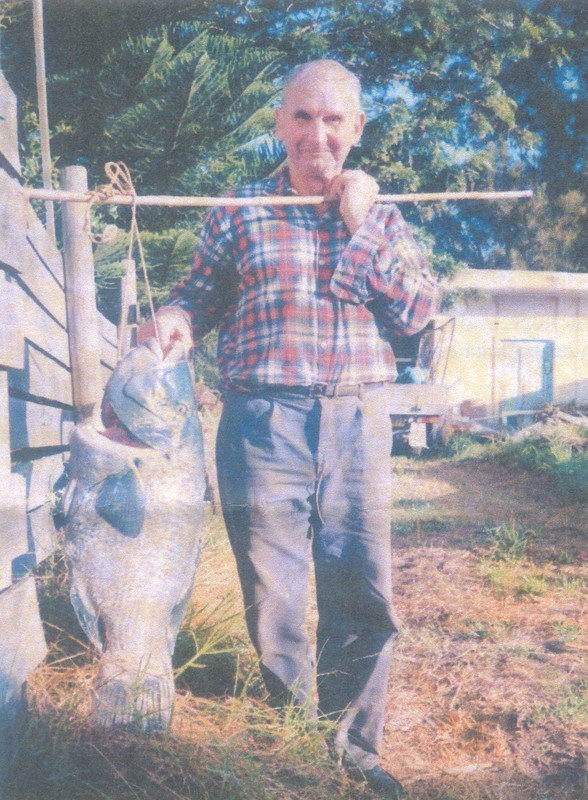

Dried and Smoked fish. Also during WW2 Kevin and his father used to bicycle to Connells Point (now Mossy Point, see the entry for Connells Point in the A to Z page) from Mogo to fish and collect cuttlebone. Using mostly crabs from the rocks for bait, in a morning's fishing from the rocks they could catch as many fish as they could carry in bags on their backs. Most were dried in a wooden box about 60cm (2 feet) square with a lid. The sides had gaps about 2.5cm (1 inch) at the bottom, the bottoms and the gaps in the sides were covered by a 5cm (2 inch) layer of charcoal in the bottom of the box. The charcoal absorbed the moisture out of the fish, the outside air took the moisture from the charcoal, and the fish were thus dried and could be kept. Smoking to cure fish or meat wasn't done by the Sebbens family, Kevin thought smoking was not common.

Cuttlebone collected from Broulee Beach to form moulds for making fishing sinkers, molten lead would be poured into them. Some cuttlebone was sent to Sydney for profit, for on-selling to poultry owners.

Rabbits. As well during WW2 the family trapped rabbits across Connells (Mossy) Point as well as nearer to their home in Mogo, the meat wasn't sold it was kept for the family. The skins were dried and sent to a chap called Craig Mosten in Sydney where most went into felt hat manufacture. At that time almost all men wore a felt hat.

School. In the late 1800s or early 1900s Kevin's father Reeves James (Jim) Sebbins began school at the Tomakin school, on the rise, probably around Forrest Parade, north west of the current Tomakin Club. He moved with that school when it moved to Mogo. Kevin was born in 1929.

Wattle Bark. Wattle bark provides tannin (the brown stain seen in The Creek and The River after a lot of rain), it's used for tanning leather. Without the tannin, dried leather is hard and brittle. To harvest the tannin the bark was stripped off young trees. Kevin recalled that until the 1950s wattle bark was still being harvested at Jeremadra (from the Highway to George Bass Drive), he trucked it to be ground to a powder at a mill behind the Steampacket Hotel in Nelligen, when that mill closed it went to a mill in Wattlebark Place Moruya before being bagged and shipped to Sydney. By about the mid-1950s South Africa had obtained seeds and then, with much cheaper labour costs, took over the market.

Cuttlebone collected from Broulee Beach to form moulds for making fishing sinkers, molten lead would be poured into them. Some cuttlebone was sent to Sydney for profit, for on-selling to poultry owners.

Rabbits. As well during WW2 the family trapped rabbits across Connells (Mossy) Point as well as nearer to their home in Mogo, the meat wasn't sold it was kept for the family. The skins were dried and sent to a chap called Craig Mosten in Sydney where most went into felt hat manufacture. At that time almost all men wore a felt hat.

School. In the late 1800s or early 1900s Kevin's father Reeves James (Jim) Sebbins began school at the Tomakin school, on the rise, probably around Forrest Parade, north west of the current Tomakin Club. He moved with that school when it moved to Mogo. Kevin was born in 1929.

Wattle Bark. Wattle bark provides tannin (the brown stain seen in The Creek and The River after a lot of rain), it's used for tanning leather. Without the tannin, dried leather is hard and brittle. To harvest the tannin the bark was stripped off young trees. Kevin recalled that until the 1950s wattle bark was still being harvested at Jeremadra (from the Highway to George Bass Drive), he trucked it to be ground to a powder at a mill behind the Steampacket Hotel in Nelligen, when that mill closed it went to a mill in Wattlebark Place Moruya before being bagged and shipped to Sydney. By about the mid-1950s South Africa had obtained seeds and then, with much cheaper labour costs, took over the market.